smart manufacturing market is a rapidly growing sector that utilizes advanced technologies and data-driven decisions to optimize production processes. This article explores the impact of smart manufacturing on various industries, including medical LSR (Liquid Silicone Rubber) applications, and highlights the role of JVTECH in this transformative journey.

The Rise of Smart Manufacturing

In recent years, the smart manufacturing market has witnessed exponential growth due to advancements in automation, artificial intelligence (AI), and Internet of Things (IoT). By integrating these technologies into traditional manufacturing processes, companies can enhance productivity, reduce costs, and improve overall efficiency.

One key aspect of smart manufacturing is data-driven decision-making. With sensors embedded throughout production lines, real-time data is collected and analyzed to identify bottlenecks or inefficiencies. This enables manufacturers to make informed decisions based on accurate insights rather than relying solely on intuition or guesswork.

Revolutionizing Medical LSR Applications

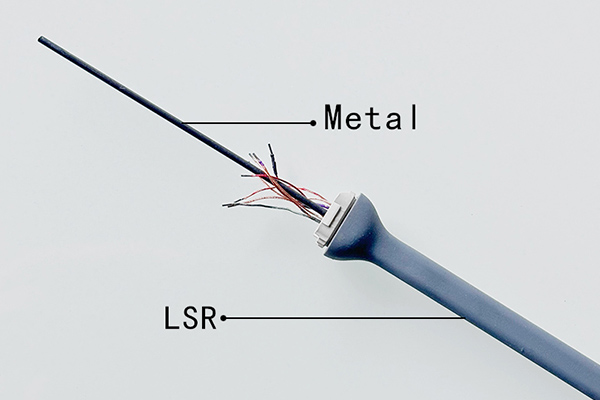

medical lsr applications have greatly benefited from the implementation of smart manufacturing techniques. Liquid Silicone Rubber is widely used in medical devices such as implants, catheters, and seals due to its biocompatibility and durability.

By leveraging data-driven decisions in the production process for medical LSR components, manufacturers can ensure consistent quality control while minimizing waste. Real-time monitoring allows for immediate adjustments if any deviations occur during production parameters such as temperature or curing time. This not only improves product reliability but also reduces costs associated with rework or scrap materials.

JVTECH: Pioneering Innovation in Smart Manufacturing

JVTECH has emerged as a leading player in the field of smart manufacturing solutions. Their expertise lies in developing cutting-edge technologies that enable seamless integration of automation, AI, and IoT into existing manufacturing systems.

Through their advanced analytics platforms, JVTECH helps companies harness the power of data to optimize production processes. By identifying patterns and trends in real-time data streams, manufacturers can proactively address potential issues before they escalate. This predictive maintenance approach minimizes downtime and maximizes productivity.

The Future of Smart Manufacturing

The smart manufacturing market is poised for continued growth as more industries recognize its transformative potential. With advancements in technologies such as machine learning and robotics, the possibilities are endless.

Data-driven decisions will continue to be at the core of smart manufacturing strategies. By leveraging real-time insights, companies can streamline operations, reduce costs, improve product quality, and ultimately gain a competitive edge in today’s fast-paced global market.

In conclusion, the smart manufacturing market has revolutionized industries by enabling data-driven decisions that optimize production processes. From medical LSR applications to pioneering companies like JVTECH, this transformative journey has paved the way for increased efficiency and competitiveness across various sectors. As technology continues to advance rapidly, embracing smart manufacturing will become increasingly crucial for businesses seeking sustainable success in an ever-evolving marketplace.