Servo drive system is a crucial component in modern industrial automation. It plays a vital role in controlling the motion of machinery and ensuring precise positioning, speed, and torque control. In this article, we will explore the benefits of servo drive systems and discuss the necessary skills for utilizing them effectively.

The Power of Servo Drive System

Servo drive systems offer numerous advantages in various industries. Firstly, they provide exceptional accuracy and repeatability, allowing for precise control over movements. This level of precision is essential in applications such as robotics, CNC machines, and packaging equipment where even slight errors can lead to significant consequences.

Secondly, servo drives offer high-speed capabilities that enable rapid acceleration and deceleration without sacrificing accuracy. This feature enhances productivity by reducing cycle times and increasing overall efficiency.

Furthermore, servo drives have excellent dynamic response characteristics. They can quickly adjust their output based on feedback from sensors or other external factors to maintain stability during operation. This capability ensures smooth performance even when dealing with sudden changes or disturbances.

In addition to these benefits, modern servo drive systems often come equipped with advanced features like network connectivity for seamless integration into complex automation setups.

The Role of Leadshine

Leadshine is a prominent manufacturer known for its high-quality servo drive systems. Their products are widely recognized for their reliability and performance across various industries worldwide.

Leadshine’s servo drives incorporate cutting-edge technology that allows for precise control over motor movements while maintaining stability under varying loads or environmental conditions. These drives also offer flexible configuration options to meet specific application requirements efficiently.

Moreover, Leadshine provides comprehensive technical support services to assist customers in optimizing their use of servo drive systems effectively. With their expertise and commitment to customer satisfaction, Leadshine has become a trusted partner for many businesses seeking reliable motion control solutions.

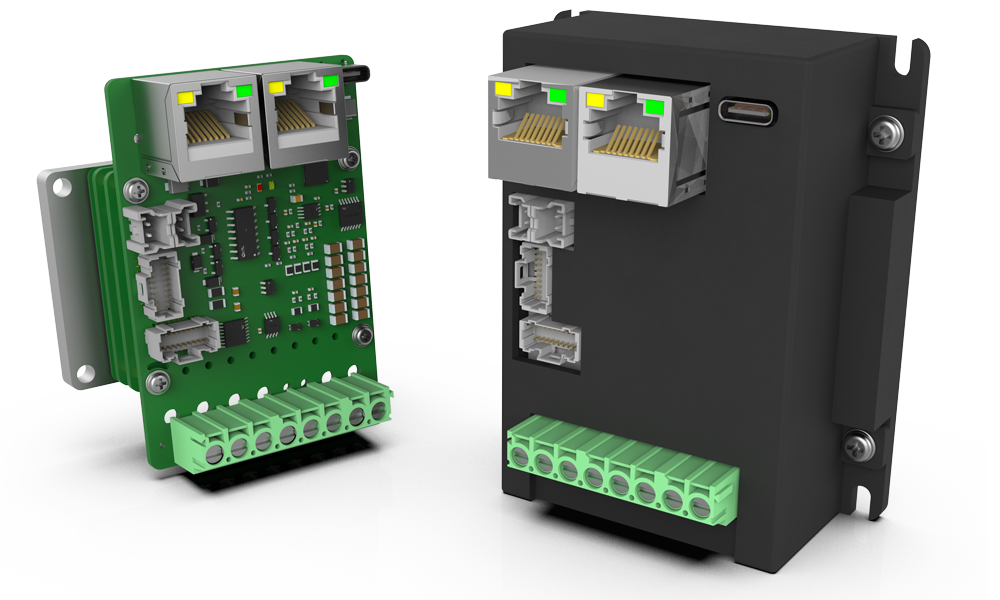

The Advantages of Integrated Stepper

integrated stepper systems are another popular choice in the field of industrial automation. These systems combine the benefits of stepper motors and drive electronics into a single integrated unit, simplifying installation and reducing wiring complexity.

Integrated steppers offer precise positioning capabilities similar to servo drives but at a lower cost. They excel in applications that require high torque at low speeds or when continuous rotation is not necessary.

Furthermore, integrated steppers provide excellent holding torque even when power is disconnected, ensuring stability during power outages or emergency situations. This feature makes them suitable for applications where safety is critical.

In Conclusion

Servo drive systems are indispensable in modern industrial automation due to their exceptional accuracy, speed capabilities, and dynamic response characteristics. Manufacturers like Leadshine have played a significant role in advancing this technology by providing reliable and high-performance servo drives along with comprehensive technical support services. Additionally, integrated stepper systems offer an affordable alternative for specific applications that prioritize precise positioning over continuous rotation. As industries continue to evolve, mastering the skills required to effectively utilize these motion control technologies will be crucial for success.