If you’ve ever wondered how pp yarn filter cartridge making machines work, you’re in the right place! These machines are essential for producing high-quality filter cartridges used in various industries. Let’s dive into the fascinating world of PP yarn filter cartridge manufacturing.

The Basics of PP Yarn Filter Cartridge Making Machine

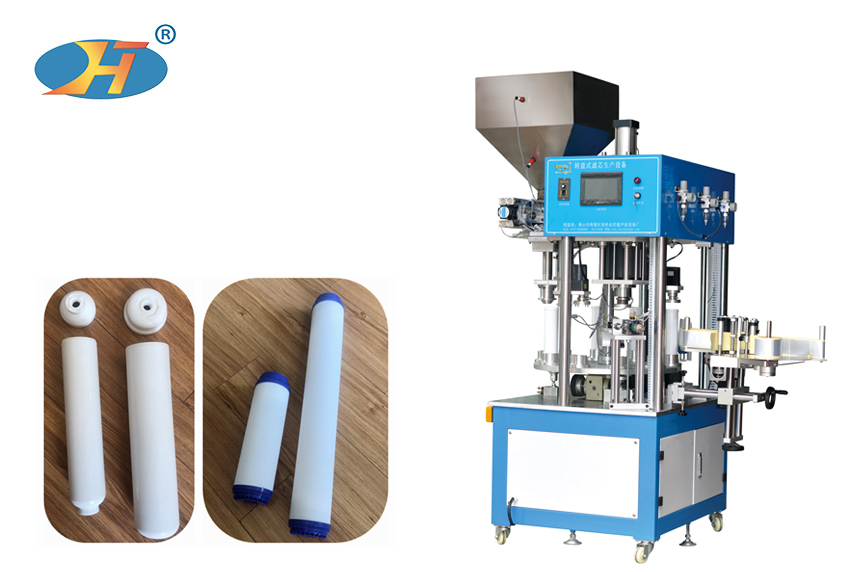

A PP yarn filter cartridge making machine is a specialized equipment designed to produce filter cartridges made from polypropylene (PP) yarn. It involves several steps, including winding, cutting, sealing, and assembly. The machine ensures precise control over each stage to create durable and efficient filters.

Find more about spun filter cartridge manufacturing machine.

The Process of Spun Filter Cartridge Manufacturing

In the first step of spun filter cartridge manufacturing using a PP yarn filter cartridge making machine, the polypropylene yarn is wound onto a core or bobbin. This process creates layers that provide filtration capabilities. Then, the wound material is cut into desired lengths and sealed at both ends to prevent any bypassing during filtration.

Next comes the assembly phase where these individual cartridges are fitted into a housing or frame to form complete filters ready for use. The entire process is automated and optimized for efficiency and accuracy.

Hongteng: A Leading Manufacturer in this Field

When it comes to reliable manufacturers of PP yarn filter cartridge making machines, Hongteng stands out as one of the best in the industry. With years of experience and expertise, they offer top-notch machinery that meets international standards.

Hongteng’s machines incorporate advanced technology and innovative features to ensure seamless production processes with minimal downtime. They also provide excellent after-sales support and customization options according to specific client requirements.

In Conclusion

PP yarn filter cartridge making machines play a crucial role in the production of high-quality filters used in various applications. From winding and cutting to sealing and assembly, these machines ensure precise control over each step to create efficient and durable filter cartridges.

With manufacturers like Hongteng leading the way, you can trust that the industry will continue to advance with improved technologies and enhanced capabilities for producing top-of-the-line PP yarn filter cartridge making machines.